Coldchain Technology Services, located in Spring Branch, Texas, was founded in 2006 and is a Service Disabled Veteran Owned Small Business focused on providing cold chain management solutions for the storage and distribution of time temperature sensitive products. CTS qualifies as a small business under the NAICS code 322212, size standard 750. CTS operations meet or exceed current Good Manufacturing Practices (cGMP) regulatory compliance standards as outlined by the FDA and are VAAWD accredited for drug distribution and supply chain design.

Primary Performance Location San Antonio, Texas

Assets in Portland | Bethesda | Chicago | Sneek Netherlands

Background

Global Medical Material Supply Chain Solutions Provider

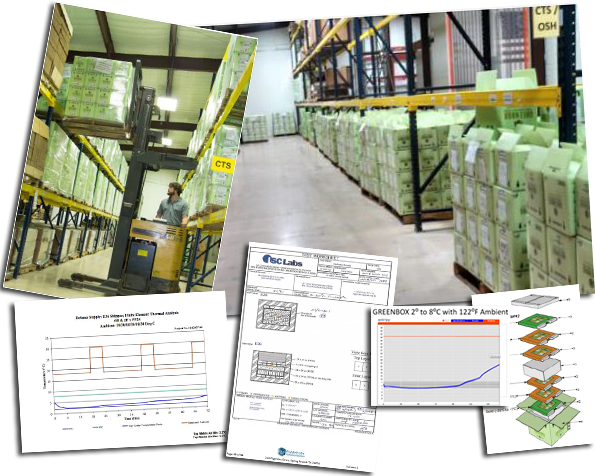

CTS has extensive experience helping develop shipping systems, supply of thermal shippers, development of shipping protocols, managing drugs, supplies, and emergency asset materials. CTS’s founder and owner was the Associate Director of Logistics for the Centers for Disease and Control and Prevention’s Strategic National Stockpile (SNS) from inception throughout its rapid post 9/11 ramp-up and continues to provide Subject Matter Expertise to the program. CTS continues a strong tradition of innovation and being first, introducing new industry-defining systems, technologies, quality programs, compliance processes, and enterprise wide inventory optimization initiatives. One example of CTS innovation is the development and use of the reusable high performance insulated thermal shipper under a closed loop system of supply and reclamation including full disassembly and sanitization (per the Validated SHIP2Q Process) of the shipper prior to reuse. This innovative system reduces landfill waste by 100%, improves performance, and allows for the shipper to be used up to 50 times before it is fully recycled and repurposed delivering significant cost savings to the client. CTS and its founder.

have developed sophisticated logistics management services and readiness-related software applications for multiple government and commercial clients, including the US Army, the Centers for Disease Control and Prevention, Reserve Component forces, Johnson & Johnson brands, Chicago Department of Public Health, and others. Our services cover the full spectrum of logistics; including selection, sourcing, qualification testing, receipt, storage, distribution, utilization, kitting, recovery, and redistribution. CTS has set up and operated specialty warehouses supporting the H1N1 campaign and other pandemic response events. At these warehouses, CTS has supplied and maintains insulated thermal shippers and the refrigeration packs needed to kit and deploy to dispensing clinics drugs for up to six (6) million patients at once.

Performance at Location:

Medical Logistics, Medical Material Fulfillment, Controlled Environment Pharmaceutical Storage & Distribution, Emergency Services Planning and QA/QC, Temperature Monitoring Systems, Monitoring System Oversight and Alert Center, Inventory Management of Medical & Surgical Supplies, and Coldchain System Evaluation/Design

- VAWD Accredited Wholesale Distributor by the National Association of Boards of Pharmacy

- Licensed for the Wholesale Distribution of Prescription Drugs in 26+ States

- USP 1079/1083, FDA 21 CFR Part 11/210/211 & 820, ICHQ8/Q10, ISO 17025 Compliant

- FDA Part 11 Compliant Electronic Inventory Management System

- All Facilities and Materials Continuously Monitored and Electronically Controlled

- Oversee and Manage >100,000 Square Feet of cGMP/GDP Facility Space

- Independently Audited and Qualified for Processing, Packing, Holding, and Distribution Finished Pharmaceuticals

- Exec Team with 80+ Years of Vaccine & Drug Logistics Subject Matter Expertise

- Maintain Electronic Inventory Management Platform for 55+ Hospitals and Chicago Department of Public Health

Capabilities

Exec Team With 80+ Years Vaccine and Medical Material Management Expertise

CTS is dedicated to serving the needs of various commercial and government agencies, with medical readiness as its core business. CTS has over 30 years of combined experience in every aspect of the cold chain management processes to include: Research and Development, First Article Testing (FAT), Validation, SOPs, Storage and Warehousing, Process Management, Distribution, Transportation, cGMP Compliance, Training, Regulatory Consulting, and Monitoring solutions. CTS designs, validates (to GDP/ICH/WHO/GMP standards), manufactures, assembles, distributes, and recovers (for repurposing or reuse) thermal shippers intended to deliver critical lifesaving medical materials around the globe. CTS’s ability to design, supply, and utilize the shipper positions CTS as a strong potential partner to help add value to the DLA mission and ensure that their distribution process delivers the highest degree of safety, efficacy, and potency of the medical materials distributed by the various DLA depots.

Coldchain Technology Services is the primary contractor to the Bureau of Health Preparedness and Emergency Response, Chicago Department of Public Health. One of the deliverables includes the design, testing, and deployment of all medical countermeasure “kits” for the Chicago metropolitan area. In 2009 during the H1N1 response, Chicago had the highest “take” rate of any other project area. During this Public Health Emergency (PHE) CTS received, correctly maintained, kitted and distributed 900,000 doses of influenza vaccine and 1.2 million doses of Tamiflu. CTS’ centralized storage, distribution and delivery of vaccine and other countermeasures follows all state and federal regulatory compliance requirements. In this effort, CTS trained 34 hospitals and 7 clinics, including providers administering dosing, on the proper storage, handling, reverse logistics of the vaccines, and retrieval of all medical waste generated during the operation. Chicago set the “gold” standard for pandemic response during this PHE, meeting or exceeding Federal goals before any other project area in the Country.

CTS personnel have a strong history with the previous DLA distribution contract(s) and supply chain distribution of medical materials for USAMAA and Mechanicsburg, PA (as well as OCONUS). We are confident that our past experience and current capacity will enable CTS to successfully perform the first article testing required to project a container meeting or exceeding the specifications & quality assurance requirements within the CID and supply these items to the various DLA depots throughout the duration of the contract. All material testing and qualification at CTS is performed under the supervision of our Medical Director (M.D.) and Director of Corporate Compliance (M.S. in Pharmaceutical Quality). These two experts drive the engineering and testing teams to ensure the highest level of design testing, qualification, product conformance, and scientific reporting in line with our corporate Master Validation Plan. CTS is the world leader in the design and production of thermal shippers to ensure supply chain distribution without compromising product safety and efficacy.

Knowledge Base Compliance & Quality Systems

CTS is a unique organization, we provide the world’s leading technology in temperature controlled shippers and perform pinpoint distribution of drugs all over the world.

CTS employs some of the leading subject matter experts in the area of medical material management and logistics for time and temperature sensitive products. Our owner, Mr. Wayne Williams, while at USAMAA, participated in developing the first evaluations, specifications, qualifications for what is the current CID and packout protocols used by the depots when loading the shippers with products for delivery. If awarded this contract, CTS will deliver both the knowledge of “what” insulated shipper to utilize plus expertise of “how” to utilize the insulated shippers from a vendor with practical experience with work similar to the DLA. CTS has the expertise to deliver the insulated thermal shipper and help the DLA with continuous improvement of its program. Past awardees (Thermosafe & CCT) are manufacturers/suppliers of shippers and do not have the knowledge or direct experience packing and distributing vaccines or drugs needed to help the DLA to address deficiencies and make proactive improvements to its distribution processes. Because CTS holds, packs, and distributes medical materials, CTS is required to meet strict regulatory compliance guidelines across our entire operation. Currently, CTS is VAWD Accredited Wholesale Distributor by the National Association of Boards of Pharmacy, licensed for the wholesale distribution of drugs in 28 states, and compliant with USP 1079/1083, FDA 21 CFR Part 11/210/211 & 820, ICHQ8/Q10, and ISO 17025 which is the accreditation standard for testing and calibration laboratories in order to be deemed technically competent (the CDC vaccine for children program does not recognize testing performed by non ISO17025 accredited organizations). The robustness of our quality control and quality assurance far exceeds the typical insulated shipper supplier and will add value to the DLA far beyond the shippers themselves.